Key Specifications:

- Maximum Glass Size:

- This defines the largest glass sheet the machine can handle. It’s often expressed in millimeters (e.g., 3000mm x 2000mm, 4200mm x 2800mm, etc.).

- Glass Thickness Range:

- This specifies the range of glass thicknesses the machine can cut (e.g., 2mm to 19mm, 3mm to 25mm).

- Cutting Speed:

- Measured in meters per minute (m/min), this indicates how fast the cutting head can move.

- Accuracy:

- This is a critical specification, indicating the precision of the cuts. It’s often expressed as a tolerance (e.g., ±0.1mm, ±0.2mm).

- Control System:

- This refers to the computer system that controls the machine. Modern CNC glass cutting machines typically use:

- PLC (Programmable Logic Controller) systems.

- Dedicated CNC software.

- Software that allows for the import of DXF files.

- Cutting Head:

- This is the component that holds the cutting wheel. Specifications may include:

- Number of cutting wheels.

- Cutting wheel materials.

- Automatic pressure adjustment.

- 360 degree rotation.

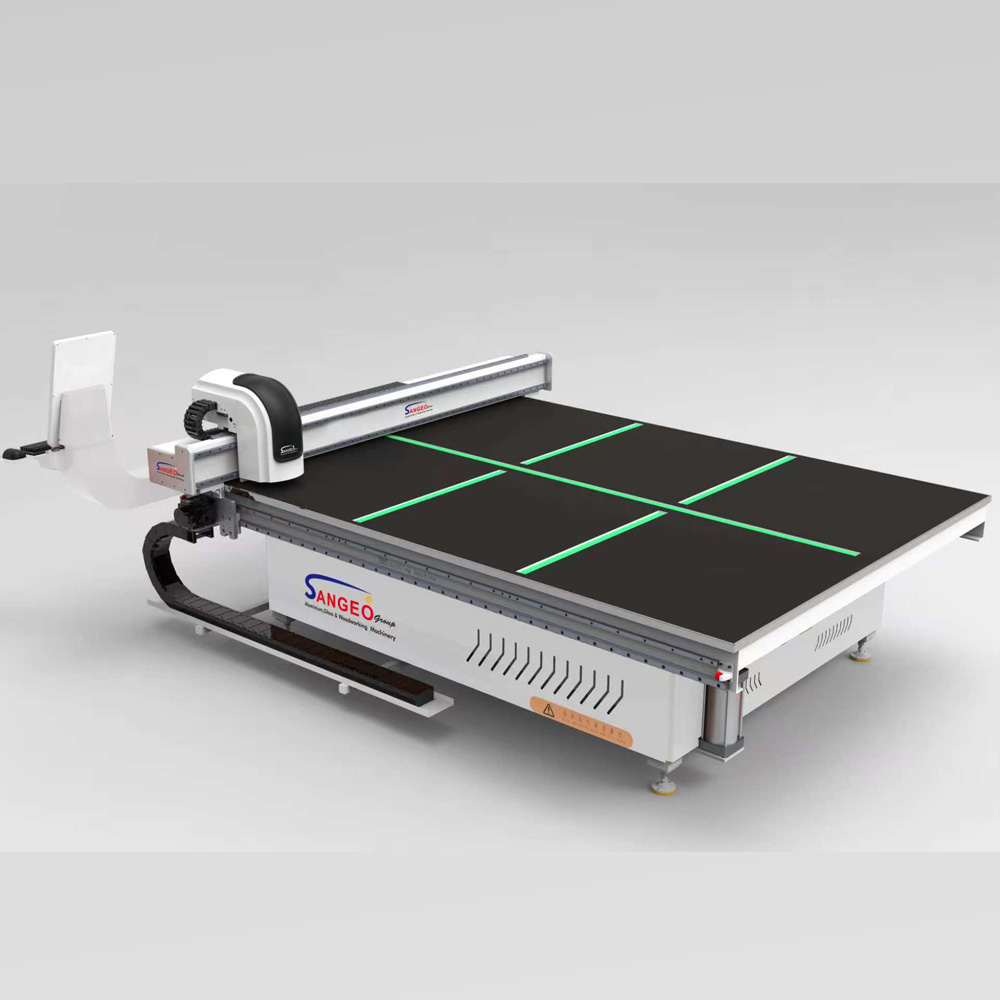

- Table and Vacuum System:

- The table holds the glass sheet in place during cutting. Specifications include:

- Table dimensions.

- Vacuum system power and effectiveness.

- Power Requirements:

- Voltage, frequency, and power consumption (kW).

- Air Pressure Requirements:

- Needed for pneumatic components.

- Software:

- Optimization software, to maximize the amount of parts that can be cut from a single sheet of glass.

- Additional Features:

- Low-E coating removal capabilities.

- Automatic labeling systems.

Where to Find Detailed Specifications:

- Manufacturer’s Documentation:

- The most accurate specifications are found in the manuals and datasheets provided by the machine’s manufacturer.

- Supplier Websites:

- Glass machinery suppliers often provide detailed product information on their websites.

Key Considerations:

- CNC glass cutting machines are highly specialized, so specifications can vary significantly between models.

- It’s essential to consider the specific needs of your glass processing operation when selecting a machine.

- The control software is a very important part of the machines capabilities.