Core Functionalities and Their Specifications:

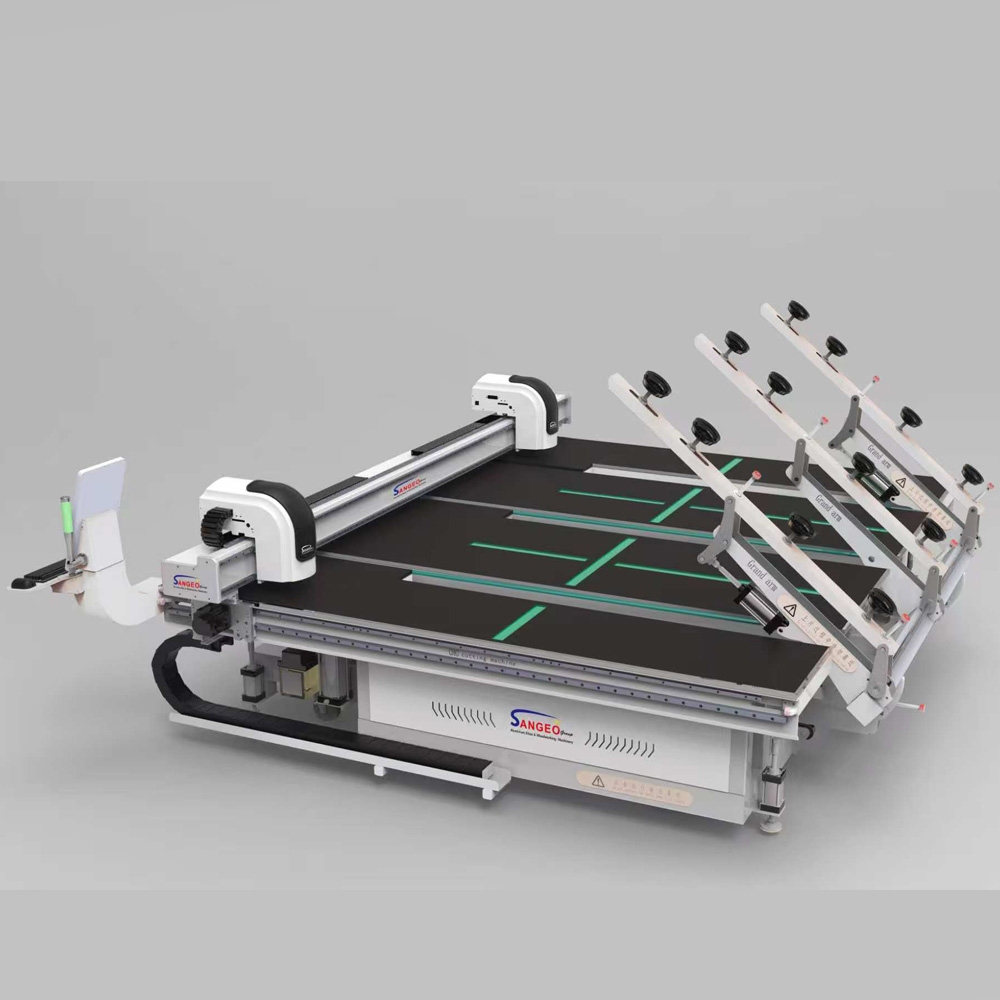

- CNC Glass Cutting:

- Maximum Glass Size:

- This defines the largest glass sheet the machine can process (e.g., 3660mm x 2440mm, 4200mm x 2800mm).

- Glass Thickness Range:

- The range of glass thicknesses the machine can cut (e.g., 2mm to 19mm, 3mm to 25mm).

- Cutting Accuracy:

- The precision of the cuts, often expressed as a tolerance (e.g., ±0.1mm, ±0.2mm).

- Cutting Speed:

- Measured in meters per minute (m/min).

- Control System:

- PLC control, PC-based control, software compatibility (DXF files).

- Low-E Deletion:

- Deletion Method:

- Mechanical (grinding wheels, brushes) or laser deletion.

- Deletion Area:

- Adjustable deletion width.

- Capability to delete edges on shaped glass. 1

- Deletion Accuracy:

- Consistency and precision of coating removal.

- Labeling:

- Labeling Method:

- Inkjet printing, label application.

- Label Placement:

- Accuracy and consistency of label placement.

- Software integration for label design and data input.

- Label Data:

- Capability to print barcodes, QR codes, and alphanumeric data.

- General Machine Specifications:

- Power Requirements:

- Voltage, frequency, and power consumption.

- Air Pressure Requirements:

- For pneumatic components.

- Table Surface:

- Material, air flotation system.

- Safety Features:

- Emergency stops, safety sensors.

- Software:

- Optimization software for glass cutting.

- Software for label design and placement.

- Loading Arm Specifications (if included):

- Maximum Loading Weight:

- Number of Suction Cups:

- Loading Speed:

Key Considerations:

- Integration:

- How well the cutting, Low-E deletion, and labeling functions are integrated.

- Software:

- The sophistication and user-friendliness of the control and optimization software.

- Automation:

- The level of automation in the loading, cutting, deletion, and labeling processes.

- Maintenance:

- Ease of maintenance and availability of spare parts.