A glass tempering plant is a facility dedicated to transforming flat glass into tempered glass, also known as toughened glass. Tempered glass is a type of safety glass significantly stronger and more durable than regular annealed glass. This report explores the process, machinery, benefits, and considerations involved in operating a glass tempering plant.

The Tempering Process:

- Cutting: Large glass sheets are cut into desired sizes based on customer specifications.

- Washing and Inspection: The glass is thoroughly cleaned to remove any dirt or debris that could affect the tempering process. A meticulous inspection ensures no pre-existing flaws are present.

- Coating (Optional): A ceramic frit or low-emissivity (Low-E) coating can be applied for specific functionalities like aesthetics or energy efficiency.

- Heating: The glass panels enter a furnace and are heated uniformly to a temperature close to their softening point (around 600°C – 680°C).

- Quenching: Rapidly cooling the glass with jets of chilled air creates compressive stress on the outer surfaces and tensile stress in the core. This stress differential strengthens the glass significantly.

- Inspection and Testing: The tempered glass is rigorously inspected for any imperfections or distortions. Measurements are taken to ensure it meets the required safety standards.

Machinery in a Glass Tempering Plant:

- Glass Cutting Line: Automated or semi-automated equipment for precise cutting of glass sheets.

- Washing Machine: High-pressure washers with specialized detergents to ensure a spotless clean.

- Coating Line (Optional): Equipment for applying ceramic frits or Low-E coatings.

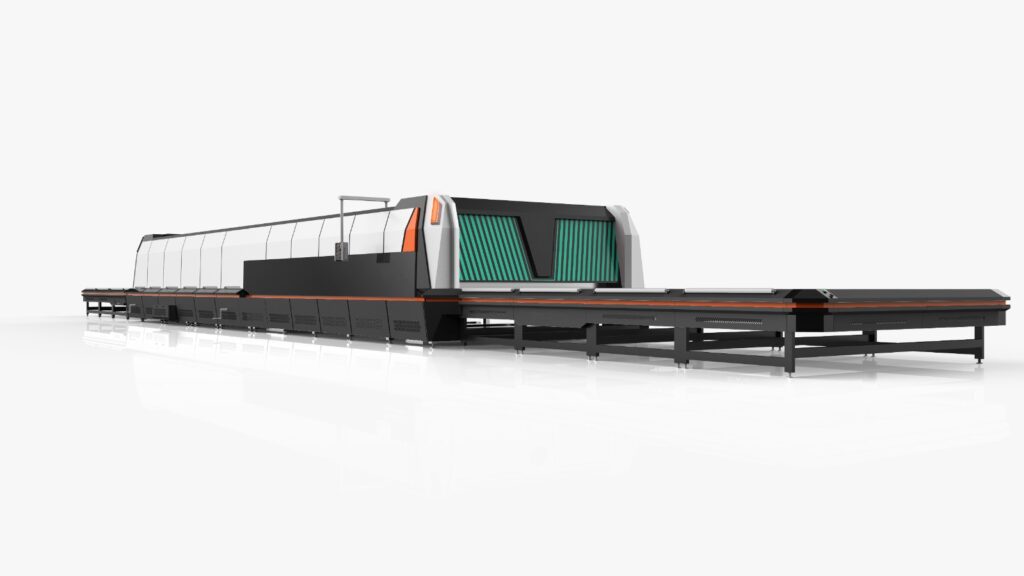

- Roller Hearth Furnace: A furnace designed to heat glass panels uniformly to the desired temperature.

- Quenching System: A system with jets of chilled air to rapidly cool the heated glass.

- Inspection and Testing Equipment: Specialized tools to inspect for surface quality, distortions, and ensure adherence to safety standards.

Benefits of a Glass Tempering Plant:

- Increased Safety: Tempered glass is several times stronger than annealed glass and shatters into small, blunt fragments upon breakage, minimizing the risk of injury.

- Improved Durability: Tempered glass is more resistant to thermal stress, scratches, and impact compared to regular glass.

- Versatility: Tempered glass can be used in various applications where safety and strength are crucial.

Considerations for Operating a Glass Tempering Plant:

- High Initial Investment: The machinery and infrastructure required for a glass tempering plant can be expensive.

- Technical Expertise: The process requires skilled personnel to operate the equipment and ensure quality control.

- Safety Regulations: Strict regulations govern the production and handling of tempered glass due to its safety-critical nature.

- Environmental Impact: The tempering process can involve significant energy consumption and require proper waste management practices.